how to make bend test machine|guided bend tests : importers ADMET bend testing machines accurately and reliably measure the flexural properties of metals, concrete, plastics, medical devices, and more. Registro/SP. Previsão numérica de tempo por período (23/02/2024) 5% Manhã. 5% Tarde. 5% Noite. 23°. 36°. Nascer do sol: 06:02 (Brasília) Pôr do sol: 18:46 (Brasília) IUV .

{plog:ftitle_list}

2 de nov. de 2023 · Leandrinha Du Art compartilhou registros íntimos com o namorado, o homem trans Izacc Medeiros. Nas imagens, os dois aparecem na cama de um quarto .

We are going to show you how to build a bend tester for your shop today. Why do you need a bend tester? PMHS Welding (Senior 2022) students build a bend tester. We walk through the steps to convert a 12Ton Press into an Air/Hydraulic 12Ton Bend Test Machine. Li.

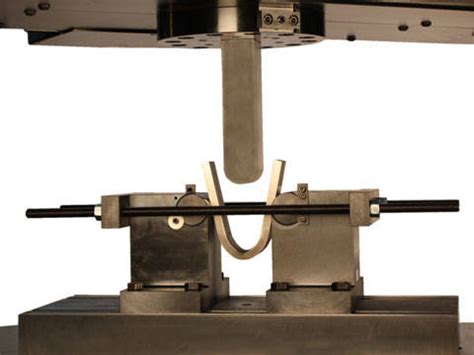

This video shows you how to build a bend test fixture used in certifying welders through bend testing. Thanks for watching and subscribing to TVWeld.#tvweld.ADMET bend testing machines accurately and reliably measure the flexural properties of metals, concrete, plastics, medical devices, and more. The welding instructor at a local vocational school has asked me to make a bend-test jig for his class. The test coupons will be 3/8 inch plate. I have sketched out some .The bend test is a simple and inexpensive qualitative test that can be used to evaluate both the ductility and soundness of a material. It is often used as a quality control test for butt-welded joints, having the advantage of simplicity of .

welding guided bend test equipment

Bend tests are usually carried out on a universal testing machine (UTM) using a 3 or 4-point bend fixture. The bend test uses a test specimen that is bent in three-point bending to a specified angle. In the Guided bend test .

bending machine capacity

Uncover the welding bend test, assessing ductility and integrity of welded connections. Explore prep steps, machinery, procedure, and quality benefits.Bend testing using a Universal Testing Machine (UTM) yields valuable data that provides insight into a material’s mechanical properties under bending or flexural stress. Here are some key data points typically obtained during a bend test:

Good Machine. For rotary draw bending, more all-electric machines are finding homes on tube shop floors. And with such machines comes more available axes of control—all important when specifying a . This video shows you how to build a bend test fixture used in certifying welders through bend testing. Thanks for watching and subscribing to TVWeld.#tvweld.The CP130604 fixture has a maximum force capacity of 20 kN and is designed specifically for tight radius bend testing of sheet metals in accordance with VDA 238-100. The punch radius, roller diameter, and roller distance are .

Our Solution. Instron’s 3-point and 4-point flexure fixtures are recommended to perform bend testing of cables and wires. Bluehill ® Universal software is implemented to set-up quick and easy methods to run bend tests at certain end-of-test conditions. Furthermore, Instron custom fixtures are designed for specific applications, such as cutting of cables and wires, to .The 3-point bending test bears this name because there are three pressure points in this test setup: Two supports and a centrally loaded test punch. The specimen lies crosswise on the supports and protrudes at the sides. The 3-point bending test is . Small-scale bending tests (Fig. 7) provide a simply fixable set-up for anchors characterization in combined shear-bending and even in equilibrium critical application.It is probably the closest combination of stresses to simulate a real-scale bended structure, which is possible through a small-scale test [97].In this case, recovery of characterization data from the .FLEX / BEND TESTING MACHINE Components and Parts. Bend tests are commonly performed on universal testing machines. These systems consist of a test frame that is equipped with a load cell, testing software, and application-specific grips and accessories, such as extensometers. The type of material being tested will determine the type of .

The test uses a universal testing machine and a three point bend fixture to bend plastic test bars to acquire the data needed to make the calculations. The calculations and set-up for D790 are more complex and time consuming compared to other tests so please read the entire specification from ASTM before running the test. ISO-180 is similar in .Universal testing machine used in Flexural testing. A Universal Testing Machine (UTM), also known as a Universal Tester, is a versatile piece of equipment that allows testing various mechanical properties of materials, including bend testing. Here are the key components of a UTM used for flexural testing: MTS Senior Application Engineer, Garrett Georgeson, demonstrates a 3-point bend test.Learn more about bend testing applications and common bend test standard.

Test setup. In the bending flexural test, a specimen is loaded under uniaxial bending stress (tension and compression) in order to obtain information on the bending behaviour of materials.Especially brittle materials such as hard metals, tool steels and grey cast iron are tested in flexural tests. In such a bending test flexural strength, deflection at fracture . So a bend test needs to be carried out in order to determine the precise value of the springback, which is dependent on the material and its thickness, and the radius to be obtained. . When using the grinding wheel cutting machine to make the horn, the hardness of the punch is decreased due to heat. ③ There’s a little bit of cracking.

This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a 3 point or 4 point bend fixture. Most common for product testing is the 3 point test. The .How much or how little a material will bend can determine its suitability for use in a product or structure. A bend test measures flexural strength, strain or stress to find out whether that material is a good choice for the intended end use. Universal testing machines outfitted with bend fixtures are used in calculating flexural strength, flexural modulus, yield point, and more. This article will explore the requisite equipment for typical testing standards as well as . cold bend testing machine.check out this item in our websitewww/nl-test.com.mywww.nl-test.comsubscribe to our channel and click the bell forfuture notificati.

A tensile tester, also known as a pull tester or univeral testing machine (UTM), is an electromechanical test system that applies a tensile (pull) force to a material to determine the tensile strength and deformation behavior until break.. A typical .It provides accurate, dependable weld-quality testing, whether used in the shop or in the field. The operator of this strap bender can set the machine to perform either an API or ASME test in mere minutes to complete any weld certification and weld inspection needs you may have, and the dual frame allows compression testing and tensile testing.

You are now ready to perform a 3-Point Bend Test. Please refer to the next section on Software Setup for programming and running the test using the Bluehill software. Next Steps: 3-Point Bend Test: Software Setup – page under construction; Previous Steps: Instron Test System OverviewA bending machine, also known as a weld bend tester, is often used for welding bend testing. To produce bending, this machine delivers regulated forces to the welded specimen. It typically includes adjustable grips or clamps to secure the specimen, a bending mechanism to apply the necessary force, and measurement equipment to quantify the .Tensile tests are performed on universal testing machines, also known as tensile machines or tensile testing machines. These machines consists of a single or dual column frame equipped with a load cell, testing software, and application-specific grips and accessories such as extensometers.Universal testing machines come in a wide variety of force capacities and can . Flexural testing, or bend testing, is a key part of basic materials characterization. This video discusses the equipment used when performing a bend test and.

TTRBM Rebar Bend and Re-bend Testing Machine is specially designed to test bend resistance performance of reinforced rolling steel bars, building steel reinforcements and steel plates which completely meet the requirement of ASTM A615, ASTM A615M, ASTM E290, BS 4449, DIN 488-2, API 5L, ISO 15630-1, ISO 7438 and other international/national . EN1288-3 (Glass in building—Determination of the bending strength of glass—Part 3: test with specimen supported at two points (four point bending), 2000) describes the four point bending test for the determination of glass strength. The failure stress is calculated from the vertical force of the testing machine.

This example of a 3-point bending test serves to show how SOLIDWORKS Simulation requires considerations to provide model stability and methods to provide that stability.. General Setup. In this setup, two rectangular bodies are created as supports with fixtures applied to their bottom faces and a single point load applied in the center of the top of the bar as .Common bend testing definitions and keywords include: Flexural strength: The maximum bending stress that the test specimen can sustain before it yields. Flexural strength measurements are expressed in force per unit area. . eXpert 1000 Series servo hydraulic testing machines are ideal for testing metals, composites, medical devices and .How to make sheet metal bending machine

Sciences et technologies - Alloprof aide aux devoirs | Alloprof

how to make bend test machine|guided bend tests